- developing mashine for 16 and 35 mm microfilm in daylight

- for film lengths of up to 305m

- variable speed up to 4m pro min

- automatic film threading and electronic monitoring of the development process

- Base cabinet with cleaning sink optional

- electronically controlled regeneration unit optional

The Film Processor PF 505 for developing microfilms is an essential part of a modern and efficient production chain.

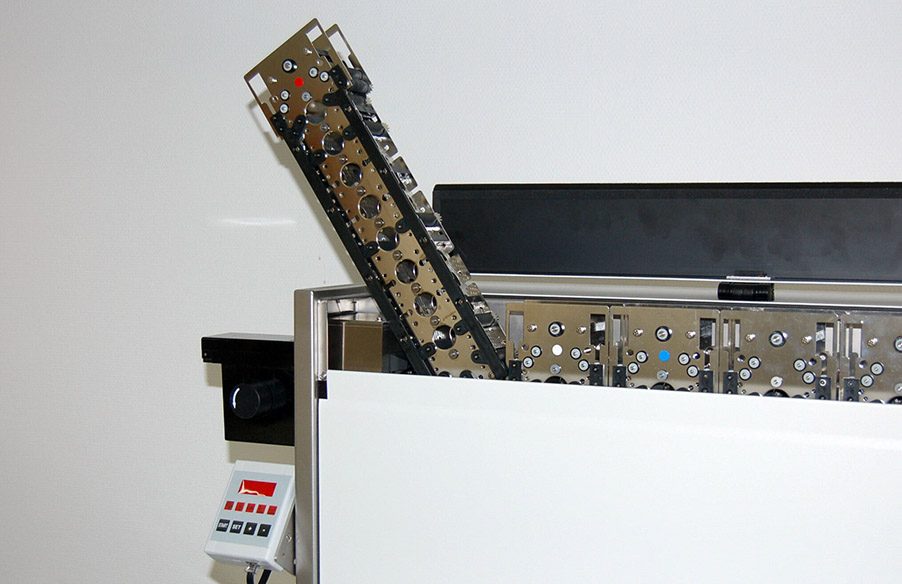

The concept of this daylight processor guarantees the best result for the high demands of microfilm processing oriented towards long-term durability, archival security and high throughput. The system is designed as a tabletop unit and can be optionally equipped with a base cabinet and cleaning basin or additionally with automatic regeneration. In the standard version, it processes 16mm and 35mm microfilms with a length of up to 66m. The films can be perforated or unperforated. Optionally, films with a length of up to 305m can be processed.

The Film Processor FP 505 is designed as a fully automatic deep tank developing system and has a fully electronic control and monitoring system with a multifunctional operator terminal. This allows the optimal developer temperatur to be controlled just as precisely as the desired transport speed and development time of the film or the optionally available fixer heating as the basis for optimal and absolutely archive-safe film processing.

Generously dimensioned and electronically monitored rinse water and dryer capacities meet all requirements for perfect archivability of the developed film material. The overall ecological concept naturally includes and automatic water shut-off at transport stop as well as the seperate collection of used chemicals. A functional design as a result of many years of experience, the stable construction made of laboratory-grade materials such as stainless steel and chemical-resistant plastics as well as the high-quality manufacturing guarantee a long service life and maximum reliability of the Film Processor FP 505 even under the thougest production conditions.

If you would like a personal consultation, please feel free to contact me!